After a long winter it was finally time to weigh the plane and determine the balance. When the balance point is too far forward or worse far aft the plane becomes unstable or unflyable.

when calculating the balance point it was clear the CG was not correct. The plane was tail heavy. we created a weight of 5.8KG and placed it on a mounting point on the floor in front of the seat. And weighted everything again. Now the position of the center of gravity was fine.

In this picture you see te plane with its tail wheel on the scale. To make a correct meassurement the plane should be horizontal

this is also specified in the flight and operating manual.

To complete the D-inspection also known as 100 hour inspection we checked some points like the allowance on control surfaces.

The checks regarding the control surfaces can only be carried out when the plane is put together. And since this was the case we took advantage of the situation

So far so good i thought.

One point remained on the cheklist and this was a check on Technical Notification 201-31, Since I did not have sufficient knowledge (will work on that in 2024-2025)An engineer explained it was a inspection on the way certain metal parts /pins where “glued” in to the wing. It’s common that cracks will occur due to the different physical properties between laminates/epoxy/ and metal. We had no luck and we discovered hairline fractures that must be repaired.

At this time the flying season seemed far away.

But I was lucky a fellow pilot and engineer with a H201 libelle was present and came to the rescue. He said that his libelle also suffered

from this and when you find this problem in time it is an relative easy fix. If you wait, water can get in between the metal an laminate and corrosion will make things worse.

Since the volume of rust is much bigger (+/-20X) than clean metal. The rust will push the laminated further away and this can make a complex repair necessary.

The metal parts than must be totally removed, cleaned snf repaired, and then everything has to be set in new composite material again to align and mount them.

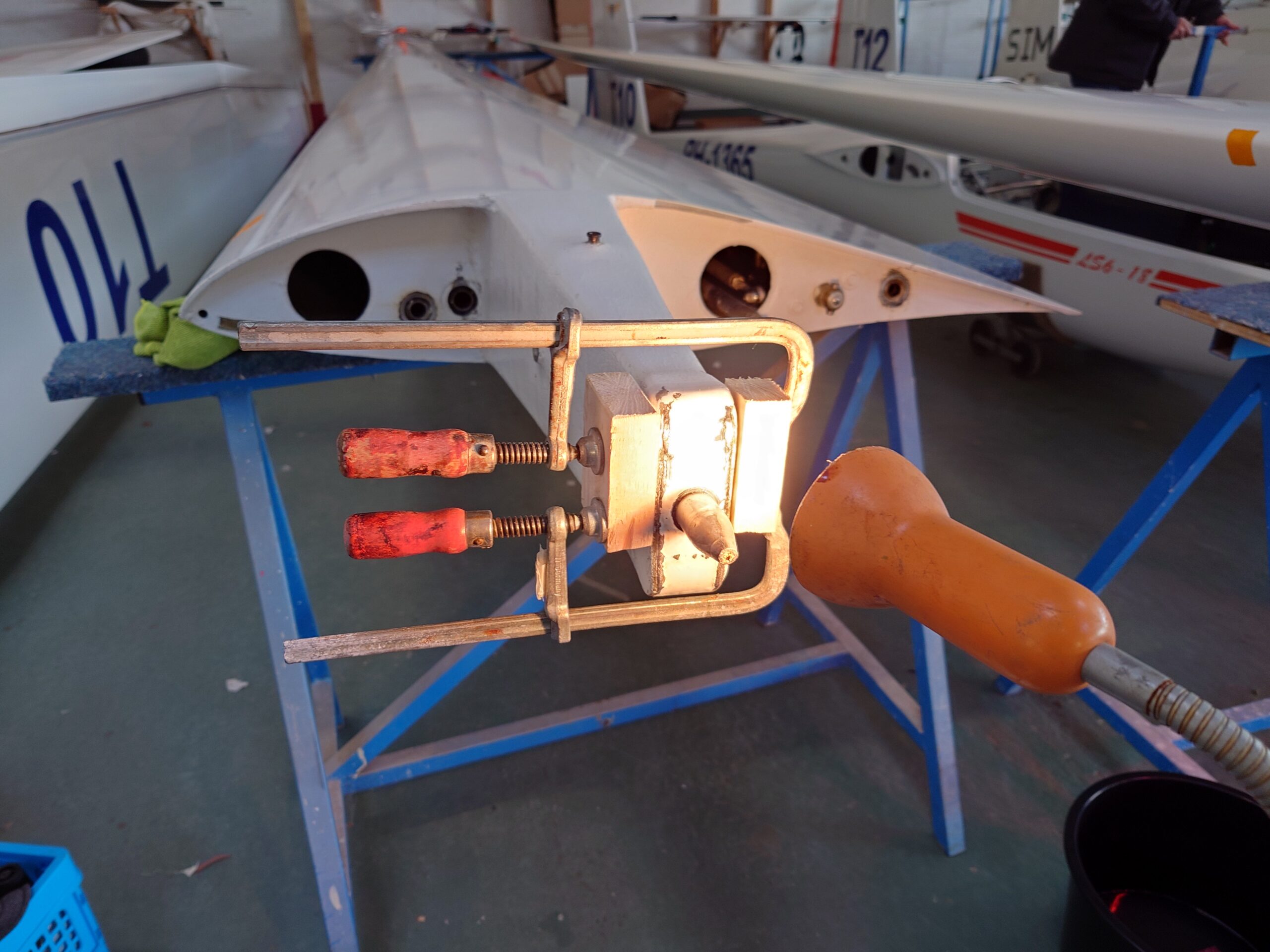

The repair was as follows, we injected some resin between the laminate and metal parts and apply clamps. We made sure with the help of some heat lamps and timer to cure the resin at 21Celsius for 12hours.

The next day we created an “oven” with an Infrared heating panel, a temperature sensor, and all kind of stuff laying around to create a “tent”

to keep the heat and harden the epoxy for another 12h at 54Celcius

A bit of sanding and painting and done !

So This concludes the annual maintenance period 2023/2024 and although there is a little list of nice to have cosmetic (paint) “repairs”. The libelle Sim is save and ready for the season 2024.:)

Leave a Reply

You must be logged in to post a comment.